Bearing Isolators

Increase the Reliability of Your Rotating Equipment

Inpro/Seal Bearing Isolators permanently protect rotating equipment from contamination ingress and lubrication loss, significantly increasing equipment reliability, reducing maintenance costs and minimizing unscheduled downtime.

The Importance of Bearing Protection

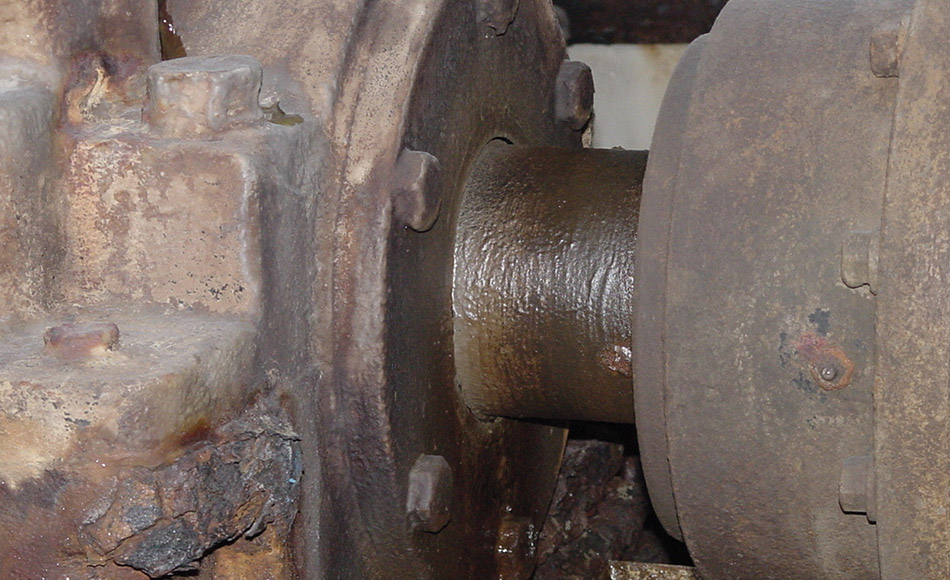

A leading cause of equipment downtime and lost production, bearing failure impacts equipment reliability across all industries. Over half of failed bearings are caused by lubrication loss and contaminants, such as dirt and moisture, entering the bearing housing. Because of this, maintenance professionals place an increased emphasis on bearing protection as a means of improving overall equipment reliability.

The High Cost of Contact Seals

Contact seals, such as lip seals, are common bearing seals that rely on mechanical contact to seal the bearing housing. Due to this, they eventually wear at the point of contact or groove the shaft, becoming ineffective. Their short and unpredictable service life makes them inadequate to seal industrial rotating equipment.

Eliminate seal failure and increase equipment reliability with a permanent sealing solution.

Permanent Bearing Protection

As the inventor of the Bearing Isolator, Inpro/Seal has delivered proven permanent bearing protection for rotating equipment, including pumps, motors, pillow blocks, gearboxes and more, for over 45 years. The Inpro/Seal Bearing Isolator’s innovative non-contacting design consists of a unitized stator and rotor that form a compound labyrinth seal with no wearing parts, ensuring permanent bearing protection against lubrication loss and contamination ingress for the lifetime of your equipment.

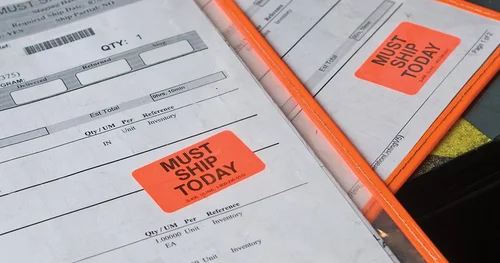

Same-Day Shipments

Inpro/Seal is committed to making sure you have the right technology, right when you need it. We know that time is money. That’s why we offer same-day shipments on most Bearing Isolators, even new and custom designs. If you require same-day shipments on an Inpro/Seal Bearing Isolator, contact your local Inpro/Seal representative.

Inpro/Seal Bearing Isolator Designs

Increase Reliability. Decrease Costs.

Inpro/Seal is a world leader in the design and manufacture of permanent bearing protection and complete shaft sealing solutions across multiple industries. We are dedicated to providing equipment reliability through engineering excellence, superior sealing technology and unmatched customer support. Read more about our application solutions or the industries we serve.

Ready to Get Started?

Count on us to improve equipment reliability through permanent bearing protection. No matter the size or complexity of the application, Inpro/Seal’s technical experts can design a custom solution for your equipment. With over 40 years of experience, we are the trusted source of Bearing Isolator technology.