Steam Turbine Bearing Isolator

Permanently protect steam turbine bearings in both high and low temperature environments.

Inpro/Seal Steam Turbine Bearing Isolators utilize multiple features to ensure effective and permanent bearing protection against contamination ingress and lubrication loss on process steam turbines. They can be custom engineered to meet the requirements of your application and operating environment.

High Temperature – above 204°C (400°F)

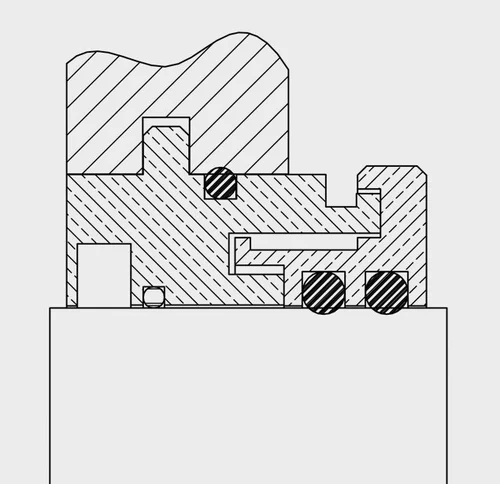

A stainless steel flinger, driven by carbon packing, deflects steam away from the bearing housing while the unique XX Interface blocks steam and other contaminants from entering the bearing housing. The extended D Groove and a coalescing ring protect against lubrication loss by capturing oil on the shaft and returning it to the bearing housing.

Features and Benefits

- XX Interface – unique stator/rotor interface provides IP66 rated permanent protection against contamination ingress

- Stainless Steel Flinger – deflects steam away from the bearings

- Carbon Packing – drives the rotor in high-temperature environments

- Contamination Chamber – collects contaminants trying to enter the bearing housing and expels them through the expulsion port through centrifugal force and gravity

- D Groove – captures oil on the shaft and returns it to the bearing housing

Technical Data

- Standard Material – Bearing Bronze and 416 Stainless Steel

- Radial Movement – 0.38 mm (0.015 in.)

- Temperature Range – up to 649°C (1,200°F)

- Speed – 10,000 sfpm

- Shaft Size – 15.88 mm (0.625 in.) to 76.20 mm (3.000 in.)

Consult an Inpro/Seal representative for operating conditions outside of limits shown.

Same-Day Shipments

Inpro/Seal is committed to making sure you have the right technology, right when you need it. We know that time is money. That’s why we offer same-day shipments on most Bearing Isolators, even new and custom designs. If you require same-day shipments on an Inpro/Seal Bearing Isolator, contact your local Inpro/Seal representative.

Ready to Get Started?

Count on us to improve equipment reliability through permanent bearing protection. With over 40 years of experience, we are the trusted source of Bearing Isolator technology.